To bolt timber to a steel beam, drill holes in the timber and beam, put bolts in the holes, and tighten them. Bolting timber to a steel beam creates a solid connection between the two materials, making it a popular construction technique.

Bolting timber to a steel beam is a common technique used in construction projects. The process involves connecting two materials, timber and steel, to create a solid structure. The timber is drilled with holes and attached to the steel beam using bolts that are tightened to create a secure connection.

This technique is often used to create larger structures such as roofs, floors, and walls. It is important to ensure that the bolts are properly tightened to prevent any loosening or slipping of the materials. In this article, we will discuss how to bolt timber to a steel beam in detail.

Credit: www.theguardian.com

Types Of Bolts To Use For Timber-To-Steel Connections

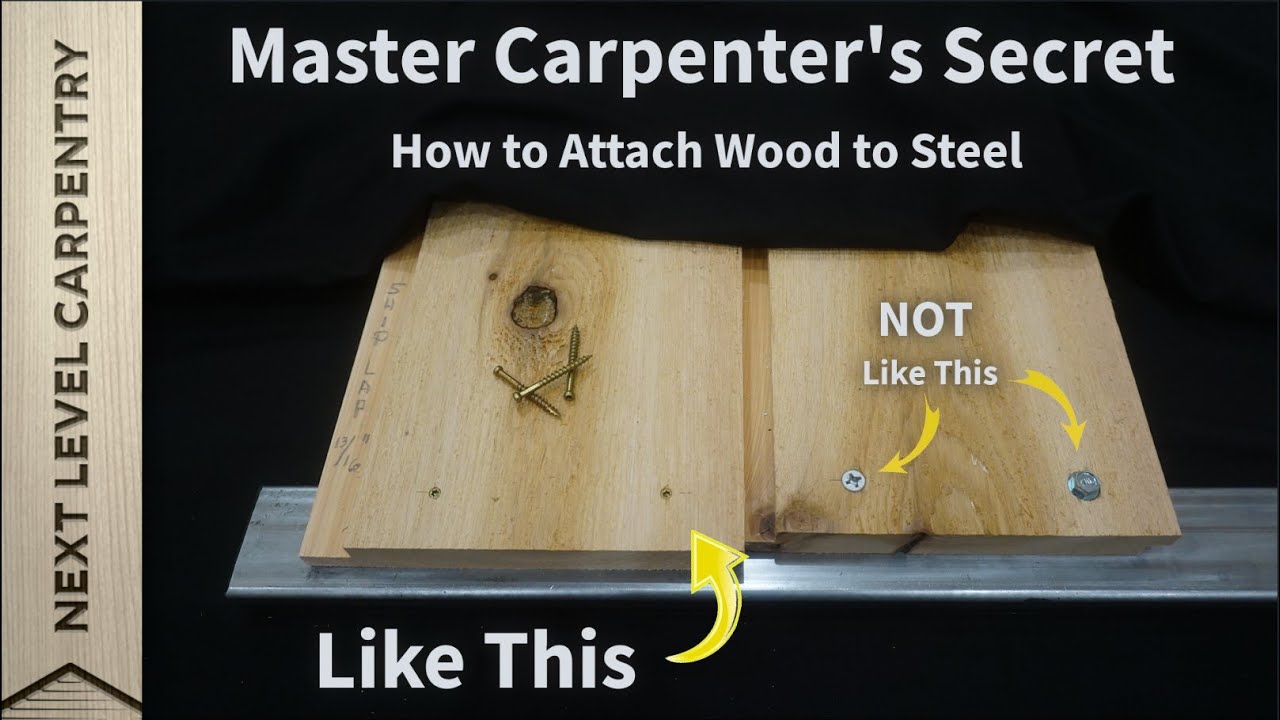

When bolting timber to a steel beam, it’s important to use the appropriate type of bolts. Lag screws and carriage bolts are commonly used for timber-to-steel connections. Each type comes with its own set of advantages and disadvantages. Lag screws are easier to install and require no washers, but they are not as strong as carriage bolts.

Carriage bolts are incredibly strong, but they take longer to install and require more tools. Additionally, choosing the correct length for the bolts is important to ensure the connection is secure. Ultimately, the choice between lag screws and carriage bolts depends on the specific project and the desired level of strength.

Types Of Hardware To Use For Timber-To-Steel Connections

There are different types of hardware to use for timber-to-steel connections. Choosing the right size and type of washers is crucial to achieve a secure fit for the bolt. Also, consider nuts and sleeves for additional support. Galvanization plays a role in the longevity of the hardware used.

It’s important to understand the impact of galvanization on bolts and hardware for long-lasting and sustainable construction. When selecting hardware, it’s important to consult with a professional to make sure the hardware chosen is appropriate for the specific project and compliant with the building code.

How To Prepare Steel Beam For Bolting

To properly bolt timber to a steel beam, it’s important to prepare the beam correctly. First, identify the steel type and thickness to ensure the correct bolts are used. Pre-drilling holes in the steel beam will also make the bolting process more efficient.

Additionally, it’s crucial to align the holes and level the steel beam. Doing so will make the entire process smoother and prevent any potential issues down the line. By following these steps, you can ensure a strong and secure connection between the timber and steel, allowing for a safe and reliable structure.

How To Prepare Timber For Bolting

Before bolting timber to a steel beam, it’s vital to prepare the timber appropriately. Choosing the appropriate size and type of timber is crucial. Pilot holes are essential for successful bolting, particularly with hardwoods. It’s critical to drill a precise pilot hole to avoid damaging the timber.

The drilling process for a pilot hole necessitates precise measurements and a steady hand. A clamp may be useful in holding the timber in place during drilling. The timber should be cleaned and free of any debris or sawdust. Following these steps will assist in ensuring that the timber is adequately prepared, and the bolting process is successful.

Step 1: Determine Proper Hole Placement

When it comes to bolting timber to a steel beam, determining proper hole placement is crucial. To achieve an accurate measurement, mark the center point of each bolt hole by measuring the distance from the timber’s edge to the center of the bolt.

Additionally, use a square to ensure the hole is perpendicular to the timber. Once you have marked all of the hole positions, drill the holes to the correct diameter and depth. Precise hole placement is vital to ensure a secure and safe connection between timber and steel.

Always measure and mark carefully to avoid any risks or complications.

Step 2: Drill Pilot Holes

To drill a pilot hole in timber, start by using the appropriate size drill bit. To make a pilot hole in a steel beam, use a high-speed steel bit. The drill speed should be slow and steady, applying light pressure as you work.

It’s important to use a pilot hole that’s the correct size for your screw or bolt. A pilot hole that’s too small can cause splitting or cracking, while a hole that’s too large leaves your fastener without enough grip. Make sure your drill bit is sharp and in good condition, and keep the drill bit perpendicular to the material as you work.

Following these guidelines will ensure your pilot holes are drilled accurately and effectively – making it easier to bolt your timber to a steel beam with precision.

Step 3: Insert Bolts And Hardware

To insert bolts through the timber and steel beam, begin by placing the washer, then the nut and bolt. Then fit a washer over the bolt and add a hexagonal or square sleeve before tightening the nuts. Ensure each bolt is tightened appropriately to achieve the maximum strength possible.

The correct torque is important as over-tightening may cause damage to the bolt or the steel beam, and under-tightening may affect the structural integrity of the bolted joint. Proper tightening will also prevent any gaps or misalignment, ensuring a safe and secure bond between the timber and the steel beam.

Safety Considerations During Bolting Process

During the bolting process of timber to steel beams, safety considerations are crucial. It is imperative to wear protective gear and safety gloves to avoid any injuries caused by the machinery or debris. Proper operation of the drill machinery ensures a precise and secure connection between the timber and the steel beam.

Over-tightening bolts can cause significant issues such as fracturing or stripping of threads and weakening of the materials. As a result, it is necessary to apply the correct torque and maintain the manufacturer’s guidelines in regards to fastening. By prioritizing safety measures and adhering to the manufacturer’s recommendations, a successful bolting process can be achieved.

Frequently Asked Questions Of Bolting Timber To Steel Beam

How Do I Bolt Timber To A Steel Beam?

To bolt timber to a steel beam, first, drill through the timber and steel, use washers and bolts with a nut on the opposite side of the timber. Tighten the nut securely.

What Are The Advantages Of Bolting Timber To A Steel Beam?

Bolting timber to a steel beam provides a solid connection that is more resistant to shear stress and movement than other connections. It is durable, easy and quick to install.

What Are The Different Ways To Bolt Timber To A Steel Beam?

There are two types of connections used to bolt timber to a steel beam: direct load transfer and indirect load transfer. It can be done with bolts, timber bolts, hex bolts, or structural screws.

Can I Bolt Timber To An Existing Steel Beam?

Yes, it is possible to bolt timber to an existing steel beam. It requires drilling a hole through the timber and steel beam and then using bolts, washers, and nuts to secure the timber to the steel.

What Is The Load Capacity Of A Bolted Timber And Steel Beam Connection?

The load capacity of a bolted timber and steel beam connection depends on various factors like timber species used and the size of the steel beam. Expert advice should be taken to ensure the structural integrity of the connection.

Conclusion

Securing timber to a steel beam can be a complex process, but when done correctly, it provides a safe and sturdy foundation for any structure. Bolting timber to a steel beam requires accuracy and precision to ensure that the integrity of the structure is preserved.

In constructing a building, where safety and stability should be the top priority, it is crucial to use reliable bolts, nuts, and washers to fasten the timber to the steel beam. Failure to follow the correct procedures and use the appropriate materials can result in disastrous consequences.

To sum things up, bolting timber to a steel beam requires careful planning, accurate measurements, and the use of appropriate tools and materials. It is always recommended to seek the expertise of professionals to ensure the job is done right.

Whether it’s a small or a big project, safety, and stability should always be given utmost concern.