Volumetric shrinkage refers to the overall reduction in the volume of a material, while linear shrinkage is the reduction in length and width. Understanding the difference between volumetric shrinkage and linear shrinkage is important in various industries such as construction, manufacturing of ceramics, and plastics.

Volumetric shrinkage occurs when the volume of a material reduces due to a change in temperature, moisture, or curing process. It affects the overall shape and size of the material; for example, a concrete structure might experience cracking due to volumetric shrinkage.

On the other hand, linear shrinkage occurs in a single direction, such as the reduction in length and width of a material. Understanding both types of shrinkage is crucial for creating accurate product designs and ensuring proper quality control measures.

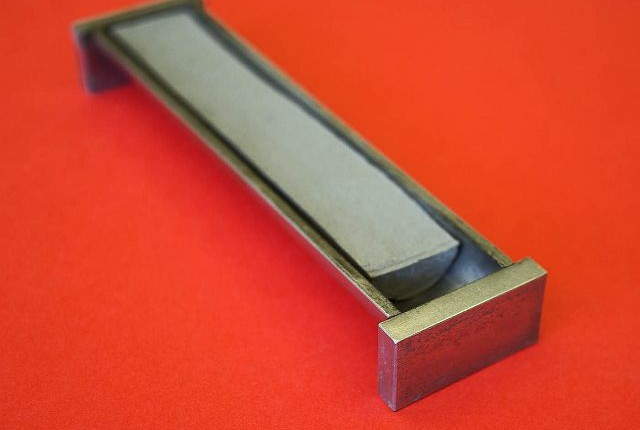

Credit: www.geolabs.co.uk

hat Is Volumetric Shrinkage?

Volumetric shrinkage refers to a change in the volume of a material during the drying process. It occurs when a material loses its moisture content and reduces in size. Examples of materials with high volumetric shrinkage include clay, soil and concrete.

Volumetric shrinkage is calculated by the difference in volume between the wet and dry weight of a material. Factors affecting volumetric shrinkage can include environmental conditions, the type of material, and the drying process used. By understanding the definition of volumetric shrinkage, calculation techniques and factors influencing it, it is possible to make better decisions when working with materials that undergo shrinkage.

What Is Linear Shrinkage?

Linear shrinkage is the decrease in length of a material in a single dimension. This phenomenon occurs when a material undergoes changes from a liquid or plastic state to a solid state. Linear shrinkage is calculated by taking the initial length of the material and dividing it by the difference in length between the initial state and the final state.

There are various factors that affect the linear shrinkage of a material, such as its composition, moisture content, and temperature. Examples of linear shrinkage include the shrinking of wood when it dries, the shrinkage of clay during firing, and the shrinkage of plastic during cooling.

Understanding the concept of linear shrinkage is important in various industries, including construction and manufacturing.

Comparing Volumetric Shrinkage Vs Linear Shrinkage

Volumetric shrinkage and linear shrinkage are two different measurements that engineers frequently use while designing any product. Volumetric shrinkage refers to the reduction in the three dimensions of an object, whereas linear shrinkage refers to a decrease in a single dimension.

These measurements help to understand the deformations and dimensional changes that occur while creating a product. Volumetric shrinkage is critical for objects with complex geometry as it can cause distortion, bending, and warping. However, linear shrinkage is essential for specific industries where products need to fit into a specific space.

The two measurements are related as volumetric shrinkage is the sum of all linear shrinkages in all dimensions. Understanding the differences between these measurements and their importance will help engineers to design high-quality products.

When To Use Volumetric Shrinkage

Volumetric shrinkage and linear shrinkage are both integral in material science. However, volumetric shrinkage may be more suitable for certain projects. For instance, when working with porcelain or ceramics, volumetric shrinkage can produce more precise outcomes, resulting in improved product quality.

Additionally, in applications with geometrically complex shapes, volumetric shrinkage can ensure that the final product meets requirements. Furthermore, in situations where material shrinkage can lead to material failure, such as in dental impressions, volumetric shrinkage plays a significant role. Therefore, in these scenarios, understanding the benefits and drawbacks of volumetric shrinkage and linear shrinkage can assist in making the best choice for the project at hand.

When To Use Linear Shrinkage

Linear shrinkage is the best choice for projects with tight tolerances. Small changes in material shape can have a huge impact on the final product’s quality. Linear shrinkage calculations are typically required in precision engineering applications. Two materials can’t be compared using volumetric shrinkage, since one might have a higher density than the other.

Linear shrinkage, on the other hand, is a more precise measure of the change in length of a material. You might need to use linear shrinkage calculations in applications such as precision metal casting, or any engineering project where accurate measurements of small dimensions are required.

Frequently Asked Questions Of Volumetric Shrinkage Vs Linear Shrinkage

What Is Meant By Volumetric Shrinkage?

Volumetric shrinkage is the decrease in the volume of a material when it undergoes a chemical or physical change like drying, cooling, and solidification.

What Is Linear Shrinkage?

Linear shrinkage is the reduction in length, width, or thickness of a material when it undergoes a chemical or physical change like drying, cooling, and solidification.

What Is The Difference Between Volumetric And Linear Shrinkage?

Volumetric shrinkage is the reduction in the volume of a material, whereas linear shrinkage is the reduction in length, width, or thickness of a material.

How Can Volumetric And Linear Shrinkage Be Measured?

Volumetric and linear shrinkage can be measured using specialised equipment, which are capable of regular and accurate measurement of samples before and after the process.

What Factors Affect Volumetric And Linear Shrinkage?

Factors that affect volumetric and linear shrinkage include the type and composition of material, temperature, humidity, drying time, cooling rate, and solidification rate.

How Important Is The Understanding Of Shrinkage For Manufacturing Industries?

Understanding shrinkage is very important for manufacturing industries, as it helps to predict the dimensional changes that materials undergo during the production process, and helps to control the quality of the final product.

Conclusion

As we have seen, both volumetric shrinkage and linear shrinkage are crucial factors that need to be taken into consideration when working with concrete. Volume and linear shrinkage can cause cracks and damage to structures, which can lead to costly repairs.

While the two types of shrinkage have similar outcomes, they have distinct characteristics and can be affected by various factors. The type of cement used, mix proportions, curing conditions, and aggregate type are among the factors that can influence the shrinkage of concrete.

Understanding the differences between volumetric and linear shrinkage can help engineers and builders design structures that are more durable and resistant to cracking. The information provided in this article can serve as a valuable guide to help you navigate the complexities of concrete shrinkage and make informed decisions throughout your building projects.